Ο ρόλος του συστήματος barcode στο χώρο των αποθηκών

Ο ρόλος του συστήματος barcode στην σύγχρονη αποθήκη.

Οι ετικέτες ραφιών αποθήκης ‘’μαρκάρουν’’ & καταχωρούν το απόθεμα που έχει αποθηκευτεί στον x διάδρομο & ταυτοποιούν τα προϊόντα που εισάγουμε στην αποθήκη με στόχο, την διαχείριση της αποθήκευσης , της διαλογής & της διαχώρισης των αποθεμάτων.

Τα είδη της ετικέτας

Παρακάτω θα δούμε τα πιο κοινά είδη ετικετών & την χρήση τους στο χώρο της αποθήκης, Τα συστήματα barcode είναι ίσως μία καλή αρχή για την κατασκευή & λειτουργία μιας σύγχρονης αποθήκης του 2023. Υπάρχουν πολλοί παράμετροι οι οποίοι επηρεάζουν την κατασκευή των ετικετών, τόσο ως προς το υλικό όσο & ως προς τις διαστάσεις.

Οι πιο σημαντικοί τύποι ετικέτας, στο κλάδο των αποθηκών είναι:

- Μαγνητικές

- 1D

- 2D

- Μεταλλικές

- LPN

- Cold Storage

- PVC

- Δαπέδου

- Εναέρια

1. Μαγνητικές

Από τις πιο ανθεκτικές ετικέτες, έχουν πανεύκολη εφαρμογή επάνω σε μεταλλικές επιφάνειες. Αφαιρούνται & επανατοποθετούνται πανεύκολα.

2. 1D

Ή αλλιώς linear barcode. Χρησιμοποιούνται κατά κόρον σε δέματα. Είναι αναγνωρίσιμα λόγω των χαρακτηριστικών γραμμών τους. Μπορούν & συνδέουν βάσεις δεδομένων, όπου έχουμε δυνατότητα να εισάγουμε νέες πληροφορίες χωρίς να αλλάξουμε τον κώδικα & κατ’ επέκταση την ετικέτα ακόμα κι αν έχει φύγει από τις εγκαταστάσεις της αποθήκης.

3. 2D

Παρόλο που τα 1d barcodes έχουν πολλές χρήσεις, έχουν περιορισμένες δυνατότητες ως προς την αποθήκευση/καταχώρηση πληροφοριών. Με το 2d επεκτείνουμε την χωρητικότητά με τη χρήση μοτίβων με σχήματα όπως εξάγωνα & τετράγωνα. Η διαφορά τους είναι ότι με την σάρωση 2d έχουμε διάβασμα του κώδικα οριζοντίως & καθέτως.

4. Μεταλλικές

Σε περιπτώσεις που απαιτούνται, ανθεκτικές λύσεις σήμανσης, η μεταλλική κατασκευή μπορεί να είναι η καλύτερη επιλογή. Ο χάλυβας με επίστρωση ουρεθάνης ή το ανοδιωμένο μέταλλο, για παράδειγμα, αντέχουν σε βαριά χρήση. Ως εκ τούτου, μπορούν να τοποθετηθούν σε παλέτες & στο δάπεδο. Οι μεταλλικές επιλογές είναι συμβατές τόσο με γραμμωτούς κώδικες 1D, όσο και με γραμμωτούς κώδικες 2D.

5. LPN

License plate number (LPN) είναι ετικέτες οι οποίες είναι προτυπωμένες & διαδοχικές & χρησιμοποιούνται για να παρακολουθούν στο σύστημα, tracking moveable μονάδες.

Με αυτή την λογική, δέματα, παλέτες & οποιαδήποτε μονάδα που εισέρχεται στην αποθήκη, παρακολουθείται με LPN. Εισάγοντας απευθείας δεδομένα, στο software παρακολούθησης αποθήκης, μπορούμε να προχωρήσουμε απευθείας σε ανάκτηση δεδομένων με την σάρωση. Είναι μια πολύ αποδοτική τακτική σε χρόνο εργασίας, καθώς ελαχιστοποιεί τον χρόνο εισαγωγής δεδομένων.

6. Cold Storage

Σχεδιασμένες ειδικά για αποθήκες που λειτουργούν σε συνθήκες ψύξης όπως αποθήκη κρεάτων.

7. PVC

Οι ετικέτες από PVC Polyvinyl chloride είναι από τις πιο συχνές σε χρήση ετικέτες ανά τον κόσμο. Η αιτιά είναι πως είναι εξαιρετικά εύπλαστες. Μπορούν να χρησιμοποιηθούν σε μορφή φύλλων σε ετικέτες με διάφορες διαστάσεις, χρώματα & πάχη. Μπορούν να αποτυπώσουν με ευκολία, πληροφορίες ασφαλείας, λογότυπα, ενδείξεις.

8. Δαπέδου

Εξαιρετικά ισχυρές ετικέτες που κολλούν στο δάπεδο. Μπορούν να σχεδιαστούν & με removable κόλα. Συνήθως είναι, απο συνθετικό υλικό, κατασκευασμένες απο πλαστικό (P.P). Είναι ιδανικές για εφαρμογές όπως μαρκάρισμα των λωρίδων & των διαδρόμων.

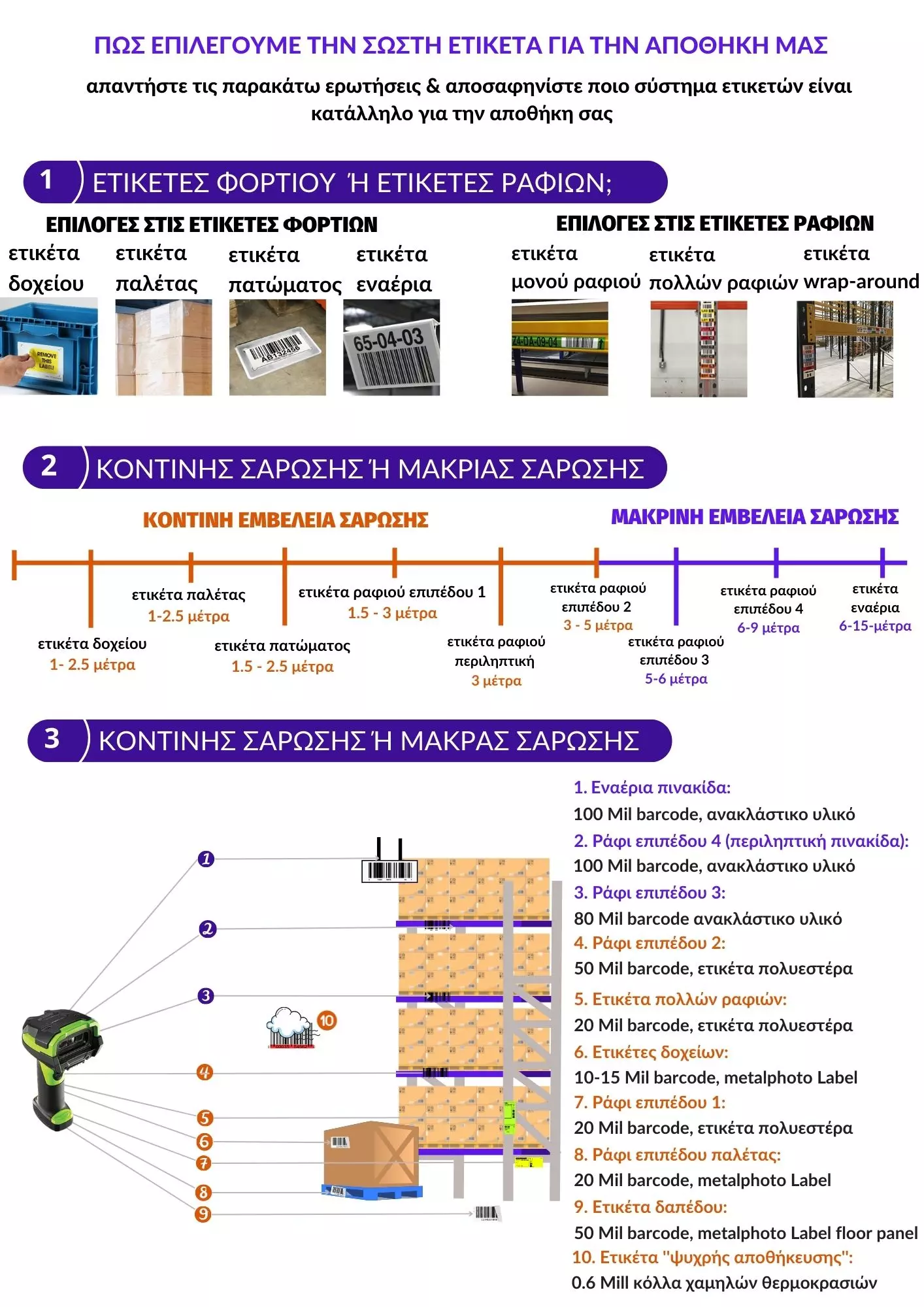

9. Χρήση ετικέτας ως προς τον χώρο.

Μπορούν να χρησιμοποιηθούν ετικέτες σε:

- Ράφια

- Ράφια παλετών

- Κάδους αποθήκευσης

- Δάπεδο

- Εναέρια, υπερυψωμένα

- Κάθετα

10. Ετικέτες που χρησιμοποιούνται για να παρακολουθούν μικρές ποσότητες & μικρού όγκου απόθεμα.

Έχοντας την δυνατότητα παρακολούθησης & των πιο μικρών δεμάτων, δοχείων κτλ. εκτός δηλαδή παλετών, μπορούμε να ενσωματώσουμε το 100% της αποθήκης στο πρόγραμμα, κάνοντας όλο το εμπόρευμα εντοπίσιμο & κατά την μεταφορά του & κατά την αποθήκευση.

11. Κάθετες ετικέτες totem

Υπάρχουν πολλά οφέλη από τη χρήση κάθετων ετικετών γραμμωτού κώδικα (ή αλλιώς τοτέμ) στις εγκαταστάσεις σας.

- Εξαλείφει την ανάγκη για σάρωση σε μεγάλη απόσταση.

- Διευκολύνει τις επιχειρήσεις ‘’pick-and-scan’’.

- Ελαχιστοποιεί τo περιθώριο ανθρώπινου λάθους & λάθους σάρωσης.

- Βελτιώνει την ακρίβεια σάρωσης του χειριστή.

- Όταν συνδυάζονται με συμπληρωματικές ετικέτες θέσης, βελτιώνει σημαντικά την ακρίβεια και την αποτελεσματικότητα.

- Επιτρέπει την ομοιομορφία σε πολλαπλές τοποθεσίες για αποτελεσματική διασταυρούμενη πλοήγηση μέσα στη αποθήκη.

12.Εναέριες

Οι ετικέτες που είναι εναέριες & σε υπερυψωμένη θέση, συνήθως είναι κατασκευασμένες από ανακλαστικό υλικό, για να έχουμε τις καλύτερες προϋποθέσεις ως προς την μακρινή εμβέλεια σάρωσης. Είναι εξαιρετικά χρήσιμες όταν δεν έχει τοποθετηθεί στο χώρο στην αρχή του διαδρόμου, κάθετο έγχρωμο τοτέμ, με κατηγοριοποίηση των ειδών που υπάρχουν στο διάδρομο, το οποίο να συμπεριλαμβάνει & τα υψηλότερα επίπεδα. Το ανακλαστικό υλικό, λόγω της έντονης ανάκλασης του φωτός δίνει καλύτερη ακρίβεια σάρωσης.

Ανάγκη για μακρινή εμβέλεια σάρωσης με τα σημερινά δεδομένα

Το πλαίσιο

Ο αριθμός των αποθηκών που επεκτείνουν τους χώρους αλλά & ο αριθμός των αποθηκών που γεννήθηκαν τα τελευταία χρόνια έχει αυξηθεί σημαντικά, την τελευταία διετία. Ο κλάδος των εταιρειών που κατασκευάζουν βιομηχανικούς επαγγελματικούς χώρους βρίσκεται σε τροχιά ανάπτυξης. Ένα ακόμα ‘’σημάδι’’ του ‘’booming’’ & των εξελίξεων που έχει επιφέρει η ραγδαία, σχεδόν, εξωπραγματική ανάπτυξη του e-commerce.

Οι ανάγκες σε bulk storage & high-capacity racking φέρνουν & τις ανάλογες αλλαγές στο θέμα των προδιαγραφών σε κατασκευή & οργάνωση.

Πλέον γίνεται εκτεταμένη εκμετάλλευση του ύψους με αποτέλεσμα, την όλο & συχνότερη χρήση των ‘’high bay’’ ραφιών στις εγκαταστάσεις. Συνεπώς, γίνεται όλο & πιο επιτακτική η ανάγκη δημιουργίας εφαρμογής πιο εξελιγμένων, νέων συστημάτων, συμπεριλαμβάνοντας & την ανάγκη για long-range scanning solutions.

Λύσεις σάρωσης μεγάλων αποστάσεων

H BLP CONNEXION μπορεί να σας, προμηθεύσει με ετικέτες ραφιών από ανακλαστικό υλικό, το οποίο υποστηρίζει τις απαιτήσεις της αποθήκης για σάρωση μακρινής εμβέλειας.

Αναλόγως, απαιτήσεων & κατασκευής αποθήκης σε συνδυασμό με τα χρήση των σωστών scanners & των κατάλληλων ετικετών μπορούμε να πιάσουμε εμβέλεια σάρωσης έως & 24 μέτρων. Εξαιρετικά βοηθητικό δεδομένο στην ροή εργασίας, το οποίο δίνει αποτέλεσμα & με ένα καταπληκτικό ROI, για αυτές τις λύσεις ετικετών.

Πλεονεκτήματα

- Βελτιωμένη ακρίβεια στο barcode scanning – βελτιώνει την παραγωγικότητα & την αναγνωσιμότητα για την εισαγωγή νέων παρτίδων & την διαλογή.

- Αυξημένη δυνατότητα εκμετάλλευσης αποθήκης – εφόσον η μεγάλή εμβέλεια στην σάρωση είναι δυνατή, η αποθήκη μπορεί να εκμεταλλευτεί & να μεγαλώσει τις δυνατότητες σε χώρο, τοποθετώντας ράφια στα υψηλότερα επίπεδα.

- Μειωμένα περιθώρια λάθους στη διαλογή - υπάρχει πλέον η δυνατότητα για ακριβή & γρήγορη επιλογή/διαλογή του σωστού εμπορεύματος.

- Μεγάλης εμβέλειας σάρωση για χρήση ετικετών αποθήκης που βρίσκονται υπερυψωμένα & εναέρια.

- Οι εναέριες ετικέτες που βρίσκονται σε υπερυψωμένη θέση, είναι εξαιρετικά χρήσιμες για την ταυτοποίησή & διαχείριση του bulk αποθέματος σε sectors των αποθηκών. Συνήθως, περιέχουν μια εικόνα barcode, & γράμματα ή αριθμούς τα οποία είναι ανθρωπίνως αναγνώσιμα.

- Έχοντας πινακίδες με αντανακλαστική ετικέτα & το κατάλληλο scanner, σημαίνει ότι το προσωπικό μπορεί να σκανάρει bulk απόθεμα χωρίς να αποχωρεί από το ανυψωτικό όχημα.

Τοποθέτηση

Πριν περάσουμε στη τοποθέτηση αυτών των ειδών ετικέτας, το δάπεδο πρέπει να έχει επαγγελματική σήμανση με λωρίδες οριοθέτησης χώρου, για μια πιο διαισθητική ροή εργασίας. Πρέπει επίσης, να έχουμε την γνώση & την εμπειρία, έτσι ώστε να τοποθετήσουμε τις πινακίδες, υπό την σωστή γωνία για να μεγιστοποιήσουμε την αποδοτικότητα σάρωσης.